Graphite Electrode Siv Rau Corundum Refining Hluav Taws Xob Arc Rauv Me Me Qhov Rooj Rauv Electrodes

Technical Parameter

Daim duab 1: Technical Parameter Rau Me Diameter Graphite Electrode

| Txoj kab uas hla | Ib feem | Kev tiv thaiv | Flexural zog | Hluas Modulus | Qhov ntom | CTE | Tshauv | |

| Ntiv | mm | μΩ hli | MPa | GPa | g/cm3 | × 10-6/ ℃ | % | |

| 3 | 75 | Hluav taws xob | 7.5-8.5 Nws | ≥9.0 | ≤ 9.3 | 1.55-1.64 Nws | ≤ 2.4 | ≤0.3 |

| Lub txiv mis | 5.8-6.5 | ≥16.0 | ≤ 13.0 | ≥1.74 | ≤ 2.0 | ≤0.3 | ||

| 4 | 100 | Hluav taws xob | 7.5-8.5 Nws | ≥9.0 | ≤ 9.3 | 1.55-1.64 Nws | ≤ 2.4 | ≤0.3 |

| Lub txiv mis | 5.8-6.5 | ≥16.0 | ≤ 13.0 | ≥1.74 | ≤ 2.0 | ≤0.3 | ||

| 6 | 150 | Hluav taws xob | 7.5-8.5 Nws | ≥8.5 | ≤ 9.3 | 1.55-1.63 Nws | ≤ 2.4 | ≤0.3 |

| Lub txiv mis | 5.8-6.5 | ≥16.0 | ≤ 13.0 | ≥1.74 | ≤ 2.0 | ≤0.3 | ||

| 8 | 200 | Hluav taws xob | 7.5-8.5 Nws | ≥8.5 | ≤ 9.3 | 1.55-1.63 Nws | ≤ 2.4 | ≤0.3 |

| Lub txiv mis | 5.8-6.5 | ≥16.0 | ≤ 13.0 | ≥1.74 | ≤ 2.0 | ≤0.3 | ||

| 9 | 225 | Hluav taws xob | 7.5-8.5 Nws | ≥8.5 | ≤ 9.3 | 1.55-1.63 Nws | ≤ 2.4 | ≤0.3 |

| Lub txiv mis | 5.8-6.5 | ≥16.0 | ≤ 13.0 | ≥1.74 | ≤ 2.0 | ≤0.3 | ||

| 10 | 250 | Hluav taws xob | 7.5-8.5 Nws | ≥8.5 | ≤ 9.3 | 1.55-1.63 Nws | ≤ 2.4 | ≤0.3 |

| Lub txiv mis | 5.8-6.5 | ≥16.0 | ≤ 13.0 | ≥1.74 | ≤ 2.0 | ≤0.3 | ||

Daim duab 2: Lub peev xwm nqa tam sim no rau me me graphite electrode

| Txoj kab uas hla | Load tam sim no | Tam sim no ceev | Txoj kab uas hla | Load tam sim no | Tam sim no ceev | ||

| Ntiv | mm | A | A/m2 | Ntiv | mm | A | A/m2 |

| 3 | 75 | 1000-1400 Nws | 22-31 : kuv | 6 | 150 | 3000-4500 | 16-25 |

| 4 | 100 | 1500-2400 Nws | 19-30 | 8 | 200 | 5000-6900 Nws | 15-21 |

| 5 | 130 | 2200-3400 Nws | 17-26 | 10 | 250 | 7000-10000 | 14-20 |

Daim duab 3: Graphite Electrode Loj & Tolerance Rau Me Qhov Loj Graphite Electrode

| Nominal Dia | Txoj kab uas hla (mm) | Nominal Ntev | Ua siab ntev | |||

| Ntiv | mm | Max. | Min. | mm | Ntiv | mm |

| 3 | 75 | 77 | 74 | 1000 | 40 | -75 ~ + 50 |

| 4 | 100 | 102 | 99 | 1200 | 48 | -75 ~ + 50 |

| 6 | 150 | 154 | 151 | 1600 | 60 | ± 100 |

| 8 | 200 | 204 | 201 | 1600 | 60 | ± 100 |

| 9 | 225 | 230 | 226 | 1600/1800 Nws | 60/72 ib | ± 100 |

| 10 | 250 | 256 | 252 | 1600/1800 Nws | 60/72 ib | ± 100 |

Daim ntawv thov tseem ceeb

- Calcium carbide smelting

- Carborundum ntau lawm

- Corundum refining

- Tsis tshua muaj hlau smelting

- Ferrosilicon cog refractory

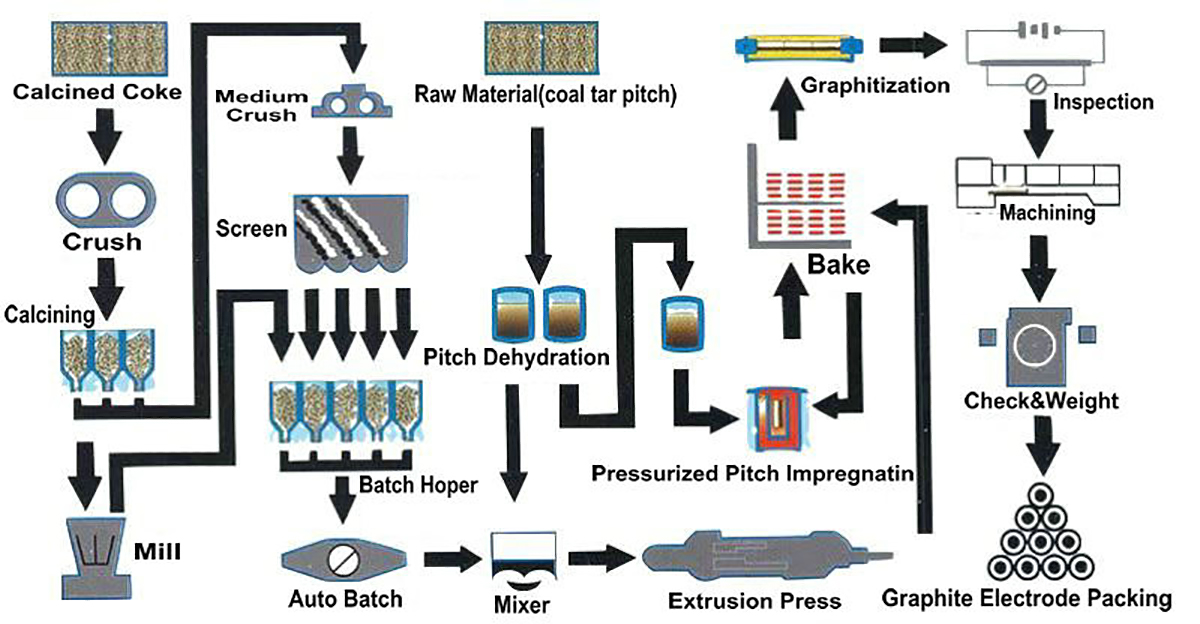

RP Graphite Electrode Ntau Lawm Txheej Txheem

Gufan Qhov Zoo

1. Ua los ntawm cov khoom siv graphite zoo, peb lub taub me me graphite electrodes yog tsim los tiv taus qhov kub thiab txias thiab muab hluav taws xob zoo heev.Qhov no ua kom cov txheej txheem smelting ruaj khov thiab ua haujlwm tau zoo, ua rau cov khoom lag luam zoo dua thiab txo qis zog noj.

2. Qhov me me ntawm cov electrodes no tso cai rau kev tswj xyuas ntau dua ntawm cov txheej txheem smelting, ua rau lawv zoo meej rau cov ntawv thov uas yuav tsum tau muaj qhov tseeb thiab cov txiaj ntsig zoo.Txawm hais tias koj tab tom tsim cov alloys lossis refining hlau, peb cov electrodes yuav pab koj ua tiav qhov kev xav tau nrog qhov tsis sib xws.

3. Peb lub cheeb me me graphite electrodes yog tsim rau ntau yam kev lag luam, nrog rau kev tsim steel, kev ua tshuaj, thiab hlau casting.Txawm hais tias qhov loj ntawm koj lub lag luam, peb cov electrodes tuaj yeem ua raws li koj qhov kev xav tau tshwj xeeb.

4. Hauv kev tsim cov hlau, peb cov kab me me graphite electrodes yog siv rau hauv cov hluav taws xob arc rauv, qhov uas lawv ua lub luag haujlwm tseem ceeb hauv kev tsim cov hlau zoo.Lawv qhov me me tso cai rau kev tswj xyuas meej ntawm cov txheej txheem melting, ua kom cov txiaj ntsig zoo ib yam thiab txo cov khoom pov tseg.

5. Hauv kev ua tshuaj lom neeg, peb cov electrodes yog qhov tseem ceeb rau kev tsim cov calcium carbide thiab kev ua kom zoo ntawm carborundum.Cov txheej txheem no yuav tsum tau tswj qhov kub thiab txias, uas peb cov electrodes xa nrog qhov tseeb tshaj plaws.

6. Rau hlau casting, peb txoj kab uas hla me me graphite electrodes yog siv nyob rau hauv smelting ntawm tsawg hlau thiab Ferrosilicon nroj tsuag.Lub superior conductivity ntawm graphite tso cai rau kom zoo melting ntawm cov hlau, uas ua rau kom ceev ntau lawm cycles thiab ntau dua tag nrho productivity.