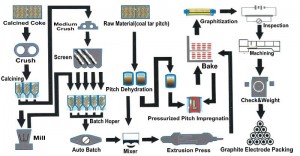

Cov txheej txheem ntau lawm ntawm Graphite Electrode

Graphite electrode yog ib hom kub resistant graphite conductive khoom tsim los ntawm kev siv roj av coke, koob coke li aggregate, thee asphalt li binder, tom qab ib tug series ntawm cov txheej txheem xws li nws, molding, roasting, dipping, graphitization thiab mechanical processing.

Cov txheej txheem tseem ceeb ntawm cov graphite electrode yog raws li hauv qab no:

(1) Calcination.Petroleum coke los yog asphalt coke yuav tsum tau forged, thiab calcination kub yuav tsum ncav cuag 1300 ℃, thiaj li kom tshem tawm tag nrho cov volatile cov ntsiab lus uas muaj nyob rau hauv cov ntaub ntawv raw, thiab txhim kho qhov tseeb ceev, mechanical zog thiab hluav taws xob conductivity ntawm coke.

(2) crushing, tshuaj ntsuam, thiab cov khoom xyaw.Cov calcined carbon raw cov ntaub ntawv yog tawg thiab soj ntsuam mus rau hauv aggregate hais txog qhov luaj li cas, ib feem ntawm lub coke yog av rau hauv hmoov zoo, thiab qhuav sib tov yog concentrated raws li cov mis nyuj.

(3) Mix.Nyob rau hauv lub tshav kub lub xeev, qhov ntau qhuav sib tov ntawm ntau yam hais yog tov nrog cov quantitative binder, tov thiab kneaded rau synthesize cov yas muab tshuaj txhuam.

(4) molding, nyob rau hauv qhov kev txiav txim ntawm sab nraud siab (extrusion forming) los yog nyob rau hauv qhov kev txiav txim ntawm high zaus vibration (vibration forming) los nias lub paste rau hauv ib tug tej yam zoo thiab siab ceev ntawm raw electrode (billet).

(5) Ci.Cov electrode nyoos yog muab tso rau hauv lub qhov cub tshwj xeeb, thiab cov hmoov coke metallurgical tau ntim thiab npog nrog cov electrode raw.Nyob rau ntawm qhov kub siab ntawm cov khoom sib txuas ntawm li 1250 ℃, roasting carbon electrode yog ua.

(6) Tsis zoo.Txhawm rau txhim kho qhov ntom ntom thiab kev kho tshuab lub zog ntawm cov khoom lag luam electrode, thiab cov kua dipping mus rau hauv qhov cua lub qhov ntawm electrode.Tom qab immersion, lub roasting yuav tsum tau nqa tawm ib zaug.Raws li kev ua tau zoo ntawm cov khoom, qee zaum impregnation thiab lwm yam roasting yuav tsum tau rov ua dua 23 zaug.

(7) graphitization.Lub ci carbon electrode yog loaded rau hauv lub qhov cub graphitization, them nrog cov khoom siv rwb thaiv tsev.Los ntawm kev siv cov txheej txheem cua sov ntawm cov hluav taws xob ncaj qha los ua qhov kub thiab txias, cov pa roj carbon electrode hloov mus rau hauv graphite electrode nrog graphite siv lead ua qauv ntawm qhov kub ntawm 2200 ~ 3000 ℃.

(8) machining.Raws li qhov yuav tsum tau siv, lub graphite electrode dawb paug nto tig, tiaj tus kawg nto thiab ntsia hlau qhov rau kev sib txuas ua, thiab kev sib koom ua ke rau kev sib txuas.

(9) Lub graphite electrode yuav tsum tau ntim kom zoo tom qab dhau qhov kev tshuaj xyuas thiab xa mus rau tus neeg siv.

Post lub sij hawm: Jun-01-2023