HP24 Graphite Carbon Electrodes Dia 600mm Hluav Taws Xob Arc Rauv

Technical Parameter

| Parameter | Ib feem | Chav tsev | HP 600mm (24 ") Cov ntaub ntawv |

| Nominal Dia | Hluav taws xob | hli (inch) | 600 |

| Max Txoj kab uas hla | mm | 613 | |

| Min Diameter | mm | 607 ib | |

| Nominal Ntev | mm | 2200/2700 Nws | |

| Max Ntev | mm | 2300/2800 Nws | |

| Min Ntev | mm | 2100/2600 Nws | |

| Tam sim no ceev | KA/cm2 | 13-21 | |

| Lub peev xwm nqa tam sim no | A | 38000-58000 Nws | |

| Tshwj xeeb Resistance | Hluav taws xob | μΩm | 5.2-6.5 |

| Lub txiv mis | 3.2-4.3 | ||

| Flexural zog | Hluav taws xob | Mpa | ≥10.0 |

| Lub txiv mis | ≥22.0 | ||

| Young's Modulus | Hluav taws xob | Gpa | ≤ 12.0 |

| Lub txiv mis | ≤ 15.0 | ||

| Kev ceev ceev | Hluav taws xob | g/cm3 | 1.68-1.72 ib |

| Lub txiv mis | 1.78-1.84 Nws | ||

| CTE | Hluav taws xob | × 10-6/ ℃ | ≤ 2.0 |

| Lub txiv mis | ≤1.8 | ||

| Tshauv Ntsiab Lus | Hluav taws xob | % | ≤0.2 |

| Lub txiv mis | ≤0.2 |

CEEB TOOM: Txhua qhov kev xav tau tshwj xeeb ntawm qhov loj me tuaj yeem muab tau.

Yuav Ua Li Cas Sib Txuas Graphite Electrode nrog Hluav Taws Xob Arc Rauv

Graphite electrodes yog cov khoom tseem ceeb hauv Electric Arc Rauv (EAF) steelmaking txheej txheem. Txawm li cas los xij, tus nqi ntawm cov txheej txheem steelmaking cuam tshuam los ntawm electrode oxidation, sublimation, dissolution, spalling, thiab tawg. Cov xov xwm zoo yog tias graphite electrode xaiv, siv, thiab kev saib xyuas tuaj yeem txo cov electrode noj. Hauv tsab xov xwm no, peb yuav tham txog yuav ua li cas xaiv cov graphite electrode thiab yuav ua li cas tswj nws kom zoo kom tau txais txiaj ntsig zoo tshaj plaws ntawm koj cov peev txheej.

Specifications

Kev sib txuam ntawm lub tshuab hluav taws xob muaj peev xwm, transformer fais fab load thiab electrode loj.

| Qhov cub muaj peev xwm | Sab hauv Dia (m) | Transformer Peev Xwm (MVA) | Graphite Electrode Txoj kab uas hla (mm) | ||

| UHP | HP | RP | |||

| 10 | 3.35 Nws | 10 | 7.5 | 5 | 300/350 |

| 15 | 3.65 ib | 12 | 10 | 6 | 350 |

| 20 | 3.95 ib | 15 | 12 | 7.5 | 350/400 ib |

| 25 | 4.3 | 18 | 15 | 10 | 400 |

| 30 | 4.6 | 22 | 18 | 12 | 400/450 |

| 40 | 4.9 | 27 | 22 | 15 | 450 |

| 50 | 5.2 | 30 | 25 | 18 | 450 |

| 60 | 5.5 | 35 | 27 | 20 | 500 |

| 70 | 6.8 | 40 | 30 | 22 | 500 |

| 80 | 6.1 | 45 | 35 | 25 | 500 |

| 100 | 6.4 | 50 | 40 | 27 | 500 |

| 120 | 6.7 | 60 | 45 | 30 | 600 |

| 150 | 7 | 70 | 50 | 35 | 600 |

| 170 | 7.3 | 80 | 60 | --- | 600/700 |

| 200 | 7.6 | 100 | 70 | --- | 700 |

| 250 | 8.2 | 120 | --- | --- | 700 |

| 300 | 8.8 ib | 150 | --- | --- | |

Kev Taw Qhia Rau Tes Thiab Siv

- 1. Tshem tawm qhov kev tiv thaiv ntawm lub qhov tshiab electrode, xyuas seb cov xov hauv lub qhov electrode puas tiav thiab cov xov tsis tiav, hu rau cov kws tshaj lij engineers los txiav txim seb cov electrode puas tuaj yeem siv tau;

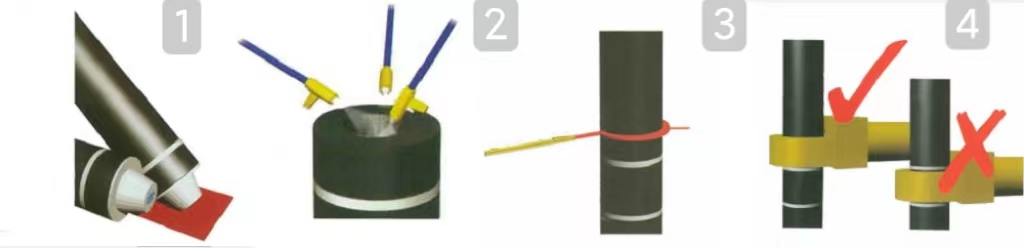

- 2.Screw lub electrode hanger rau hauv lub qhov electrode ntawm ib kawg, thiab tso lub cushion mos nyob rau hauv lwm kawg ntawm electrode kom tsis txhob ua puas lub electrode sib koom; (saib pic1)

- 3.Siv cua compressed los tshuab cov plua plav thiab sundries rau ntawm qhov chaw thiab lub qhov ntawm cov khoom siv hluav taws xob sib txuas, thiab tom qab ntawd ntxuav qhov chaw thiab qhov txuas ntawm cov electrode tshiab, ntxuav nws nrog txhuam; (saib pic2)

- 4. Nqa cov khoom siv hluav taws xob tshiab saum toj kawg nkaus ntawm qhov tseem tshuav electrode kom haum nrog lub qhov electrode thiab poob qeeb;

- 5.Siv tus nqi torque kom zoo xauv electrode; (saib pic3)

- 6.Clamp tuav yuav tsum tau muab tso tawm ntawm lub tswb kab. (saib pic4)

- 7.Nyob rau lub sij hawm refining, nws yog ib qho yooj yim uas yuav ua rau cov electrode nyias thiab ua rau tawg, sib koom ua ke poob, nce electrode noj, thov tsis txhob siv electrodes los tsa cov ntsiab lus carbon.

- 8.Dua rau cov khoom siv raw sib txawv siv los ntawm txhua lub chaw tsim khoom thiab cov txheej txheem tsim khoom, lub cev thiab tshuaj lom neeg ntawm electrodes thiab pob qij txha ntawm txhua lub chaw tsim khoom. Yog li hauv kev siv, nyob rau hauv cov xwm txheej dav dav, Thov tsis txhob sib xyaw siv electrodes thiab pob qij txha tsim los ntawm cov tuam txhab sib txawv.