High Density Me Diameter Rauv Graphite Electrode Rau Ladle Rauv Blast Rauv Hauv Hlau Smelting

Technical Parameter

Daim duab 1: Technical Parameter Rau Me Diameter Graphite Electrode

| Txoj kab uas hla | Ib feem | Kev tiv thaiv | Flexural zog | Hluas Modulus | Qhov ntom | CTE | Tshauv | |

| Ntiv | mm | μΩ hli | MPa | GPa | g/cm3 | × 10-6/ ℃ | % | |

| 3 | 75 | Hluav taws xob | 7.5-8.5 Nws | ≥9.0 | ≤ 9.3 | 1.55-1.64 Nws | ≤ 2.4 | ≤0.3 |

| Lub txiv mis | 5.8-6.5 | ≥16.0 | ≤ 13.0 | ≥1.74 | ≤ 2.0 | ≤0.3 | ||

| 4 | 100 | Hluav taws xob | 7.5-8.5 Nws | ≥9.0 | ≤ 9.3 | 1.55-1.64 Nws | ≤ 2.4 | ≤0.3 |

| Lub txiv mis | 5.8-6.5 | ≥16.0 | ≤ 13.0 | ≥1.74 | ≤ 2.0 | ≤0.3 | ||

| 6 | 150 | Hluav taws xob | 7.5-8.5 Nws | ≥8.5 | ≤ 9.3 | 1.55-1.63 Nws | ≤ 2.4 | ≤0.3 |

| Lub txiv mis | 5.8-6.5 | ≥16.0 | ≤ 13.0 | ≥1.74 | ≤ 2.0 | ≤0.3 | ||

| 8 | 200 | Hluav taws xob | 7.5-8.5 Nws | ≥8.5 | ≤ 9.3 | 1.55-1.63 Nws | ≤ 2.4 | ≤0.3 |

| Lub txiv mis | 5.8-6.5 | ≥16.0 | ≤ 13.0 | ≥1.74 | ≤ 2.0 | ≤0.3 | ||

| 9 | 225 | Hluav taws xob | 7.5-8.5 Nws | ≥8.5 | ≤ 9.3 | 1.55-1.63 Nws | ≤ 2.4 | ≤0.3 |

| Lub txiv mis | 5.8-6.5 | ≥16.0 | ≤ 13.0 | ≥1.74 | ≤ 2.0 | ≤0.3 | ||

| 10 | 250 | Hluav taws xob | 7.5-8.5 Nws | ≥8.5 | ≤ 9.3 | 1.55-1.63 Nws | ≤ 2.4 | ≤0.3 |

| Lub txiv mis | 5.8-6.5 | ≥16.0 | ≤ 13.0 | ≥1.74 | ≤ 2.0 | ≤0.3 | ||

Daim duab 2: Lub peev xwm nqa tam sim no rau me me graphite electrode

| Txoj kab uas hla | Load tam sim no | Tam sim no ceev | Txoj kab uas hla | Load tam sim no | Tam sim no ceev | ||

| Ntiv | mm | A | A/m2 | Ntiv | mm | A | A/m2 |

| 3 | 75 | 1000-1400 Nws | 22-31 : kuv | 6 | 150 | 3000-4500 | 16-25 |

| 4 | 100 | 1500-2400 Nws | 19-30 | 8 | 200 | 5000-6900 Nws | 15-21 |

| 5 | 130 | 2200-3400 Nws | 17-26 | 10 | 250 | 7000-10000 | 14-20 |

Daim duab 3: Graphite Electrode Loj & Tolerance Rau Me Qhov Loj Graphite Electrode

| Nominal Dia | Txoj kab uas hla (mm) | Nominal Ntev | Ua siab ntev | |||

| Ntiv | mm | Max. | Min. | mm | Ntiv | mm |

| 3 | 75 | 77 | 74 | 1000 | 40 | -75 ~ + 50 |

| 4 | 100 | 102 | 99 | 1200 | 48 | -75 ~ + 50 |

| 6 | 150 | 154 | 151 | 1600 | 60 | ± 100 |

| 8 | 200 | 204 | 201 | 1600 | 60 | ± 100 |

| 9 | 225 | 230 | 226 | 1600/1800 Nws | 60/72 ib | ± 100 |

| 10 | 250 | 256 | 252 | 1600/1800 Nws | 60/72 ib | ± 100 |

Daim ntawv thov tseem ceeb

- Calcium carbide smelting

- Carborundum ntau lawm

- Corundum refining

- Tsis tshua muaj hlau smelting

- Ferrosilicon cog refractory

Kev Qhia Tes Thiab Siv Rau Graphite Electrodes

1.Siv cov cuab yeej nqa tshwj xeeb rau lub neej ntawm graphite electrode kom tsis txhob puas thaum lub sijhawm thauj mus los.(saib pic1)

2. Graphite electrode yuav tsum tau khaws cia kom deb ntawm kev ntub dej lossis ntub los ntawm nag, daus, khaws cia qhuav.(saib pic2)

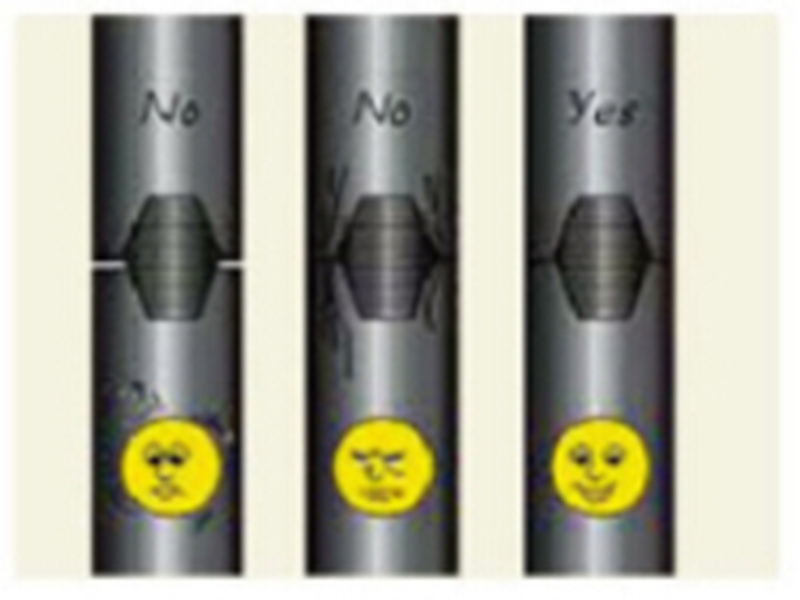

3. Ua tib zoo xyuas ua ntej siv kom paub meej tias lub qhov (socket) thiab lub txiv mis xov yog tsim nyog rau kev siv, nrog rau kev tshuaj xyuas rau lub suab, ntsaws.(saib pic3)

4. Ntxuav lub txiv mis thiab lub qhov (socket) xov los ntawm cua compressed.(saib pic4)

5. Ua ntej siv, lub graphite electrode yuav tsum tau qhuav nyob rau hauv lub cub tawg, lub ziab kub yuav tsum tsawg tshaj li 150 ℃, lub sij hawm qhuav yuav tsum ntau tshaj 30hours.(saib pic5)

6.Graphite electrode yuav tsum tau txuas nrog nruj nreem thiab ncaj nraim nrog haum nruj torque.(saib pic6)

7. Kom tsis txhob graphite electrode breakage, muab qhov loj nyob rau hauv qis txoj hauj lwm thiab me me nyob rau hauv lub Upper txoj hauj lwm.